CACOM: Continuous Cardiac Output Monitor

Orthopedic Bioengineering Research Laboratory (Stony Brook University)

Situation

Develop the initial operational sensors with necessary mechanical fixtures for verification testing

Create the basis for a research project that explores the feasibility for a wearable cardiac output device for Dr. Yi-Xian Qin’s laboratory

Conduct basic verification testing and collect basic operational dataset

Outcomes

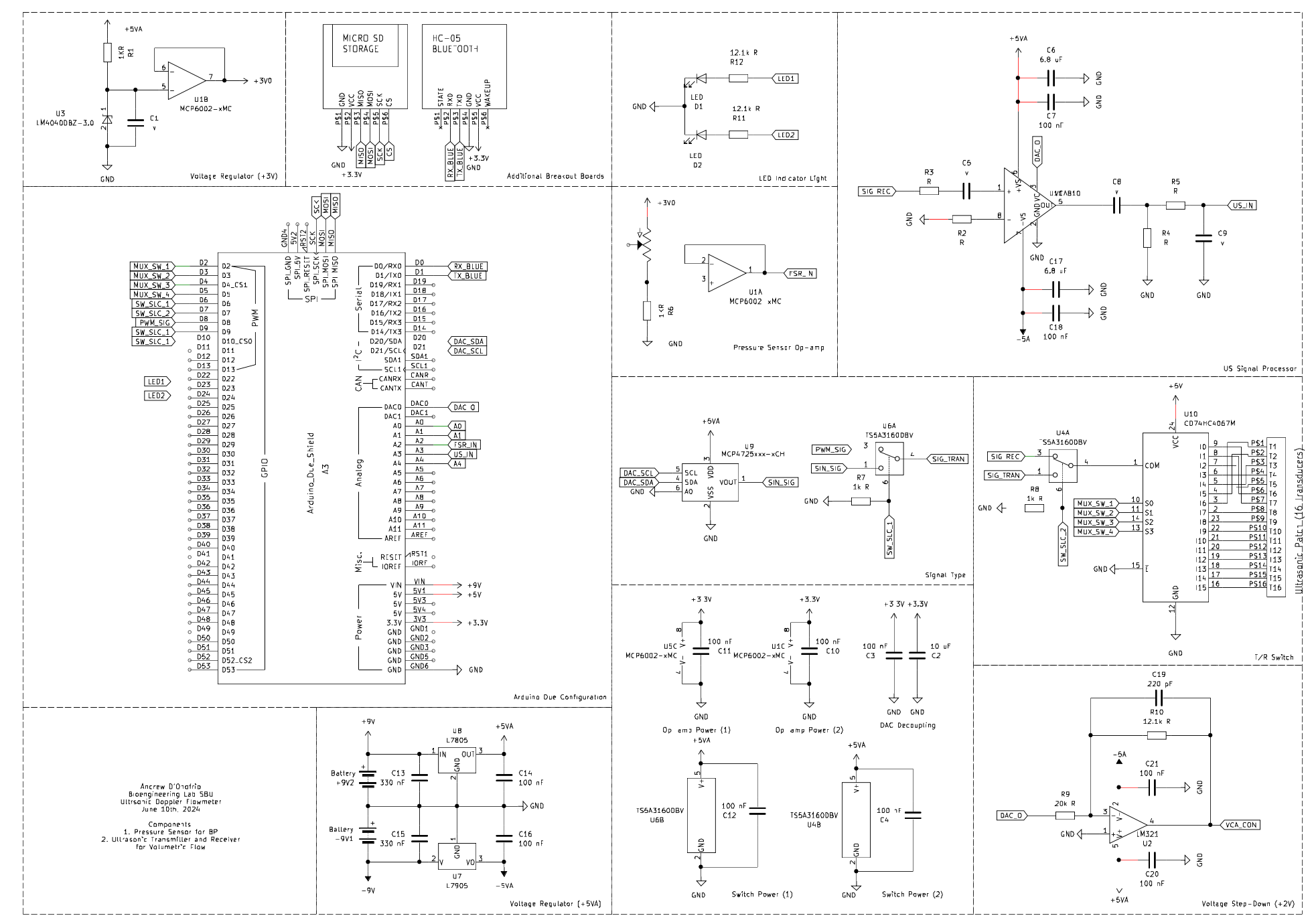

Develop Arduino-based electrical control systems through KiCAD (schematics and 2-Layer PCBs) for ultrasound sensors and pressure sensors

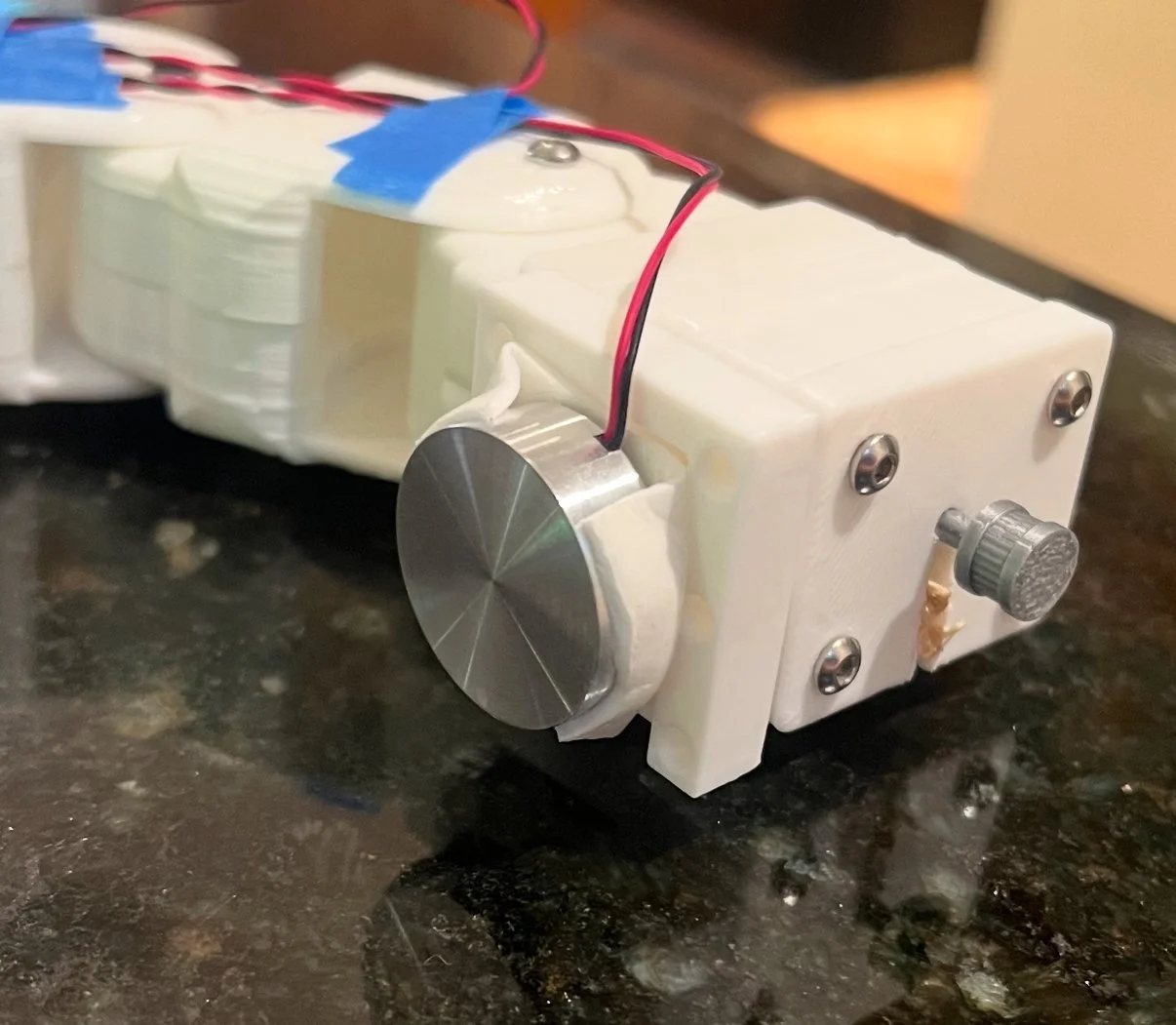

Iterated 3 mechanical prototypes with +50 PLA components in Fusion360 to fixture ultrasound and pressure sensors and provide adjustment modularity

Formulated carotid artery FEA in ANSYS for applanation tonometry to estimate arterial deformation & pressure with < 5% error

Relevant Skills

3D Modeling, Electrical Design, Verification Testing, Background Research, rapid prototyping, engineering communication/ presentation

Background

Severe and sudden myocardial infarction prevails for patients afflicted with recurrent cardiovascular events or recovering from cardiac surgeries, with the mortality rate nearly doubling for patients suffering from recurrent myocardial infarctions after the initial heart attack within a five-year recovery period.

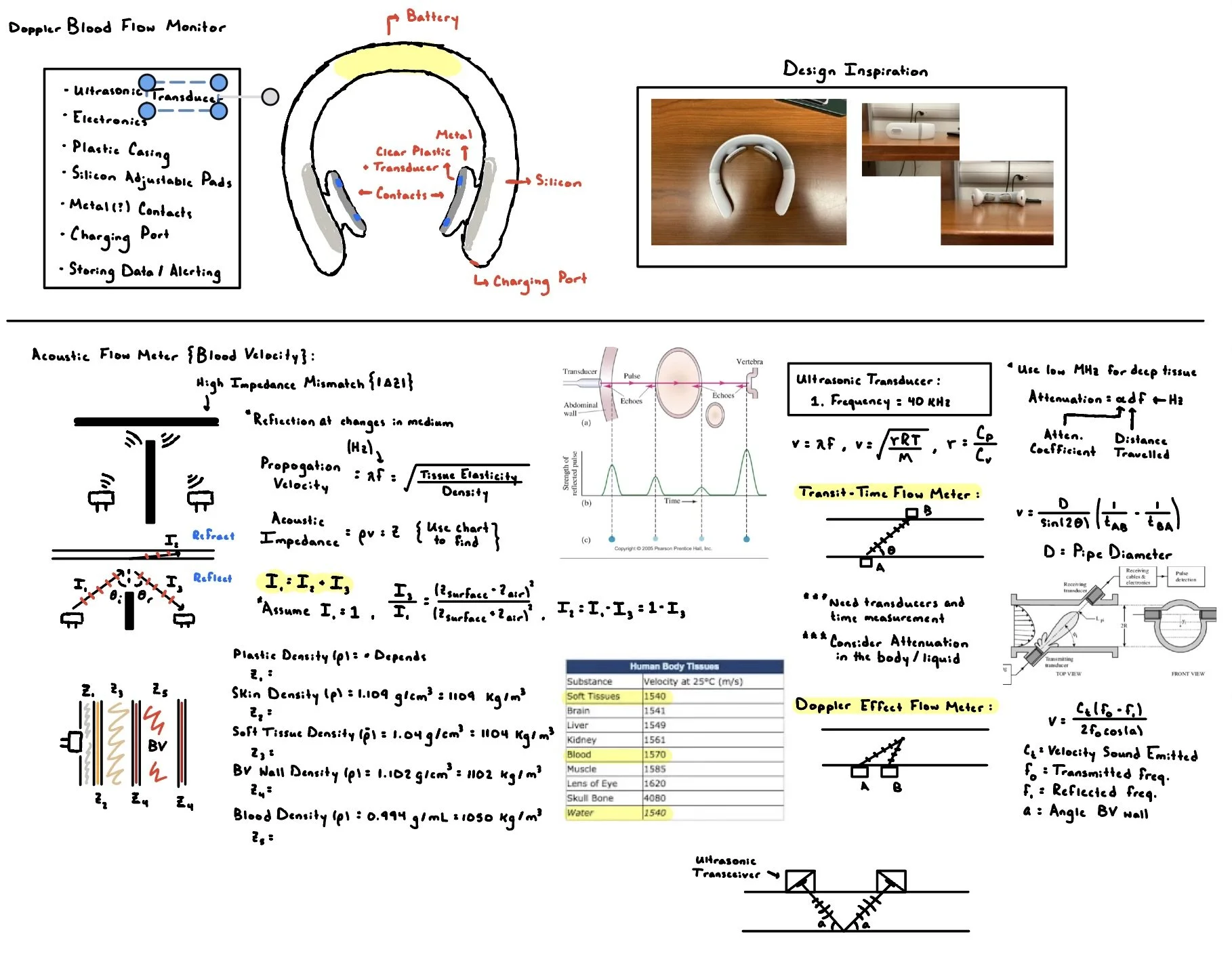

Despite the existence of reliable diagnostic technology in emergency-care centers and hospitals, few options offer realistic accessibility of at-home monitoring devices for physiological characteristics of patient’s heart health. However, with recent developments in wearable and flexible ultrasonic transducers from MIT and UC San Diego, the translation of Doppler shift flowmeters into at-home volumetric blood flow monitors is a more realistic opportunity.

Designed to rest on the patient's neck, the device is intended to continuously record data on a patient’s average blood flow through the carotid artery and arterial stiffness through various wearable sensors that are accessible for both doctors and patients through Bluetooth. Together, the Doppler ultrasonic and arterial applanation tonometry technologies provide new methods for developing personalized monitoring of cardiac output for patients diagnosed with chronic cardiovascular disease, recovering from cardiac surgery or an acute cardiovascular event, etc.

Preliminary Sensor Development

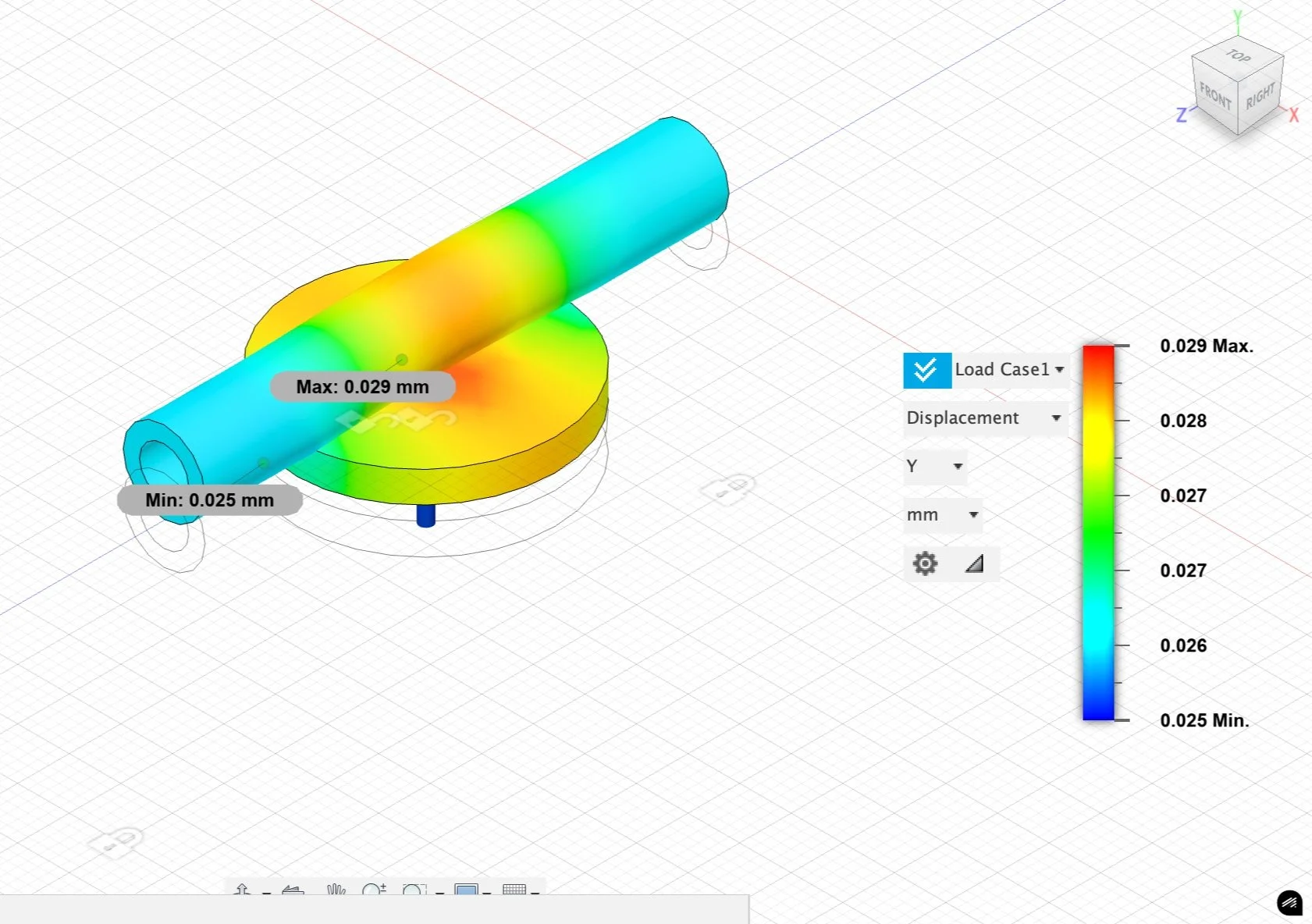

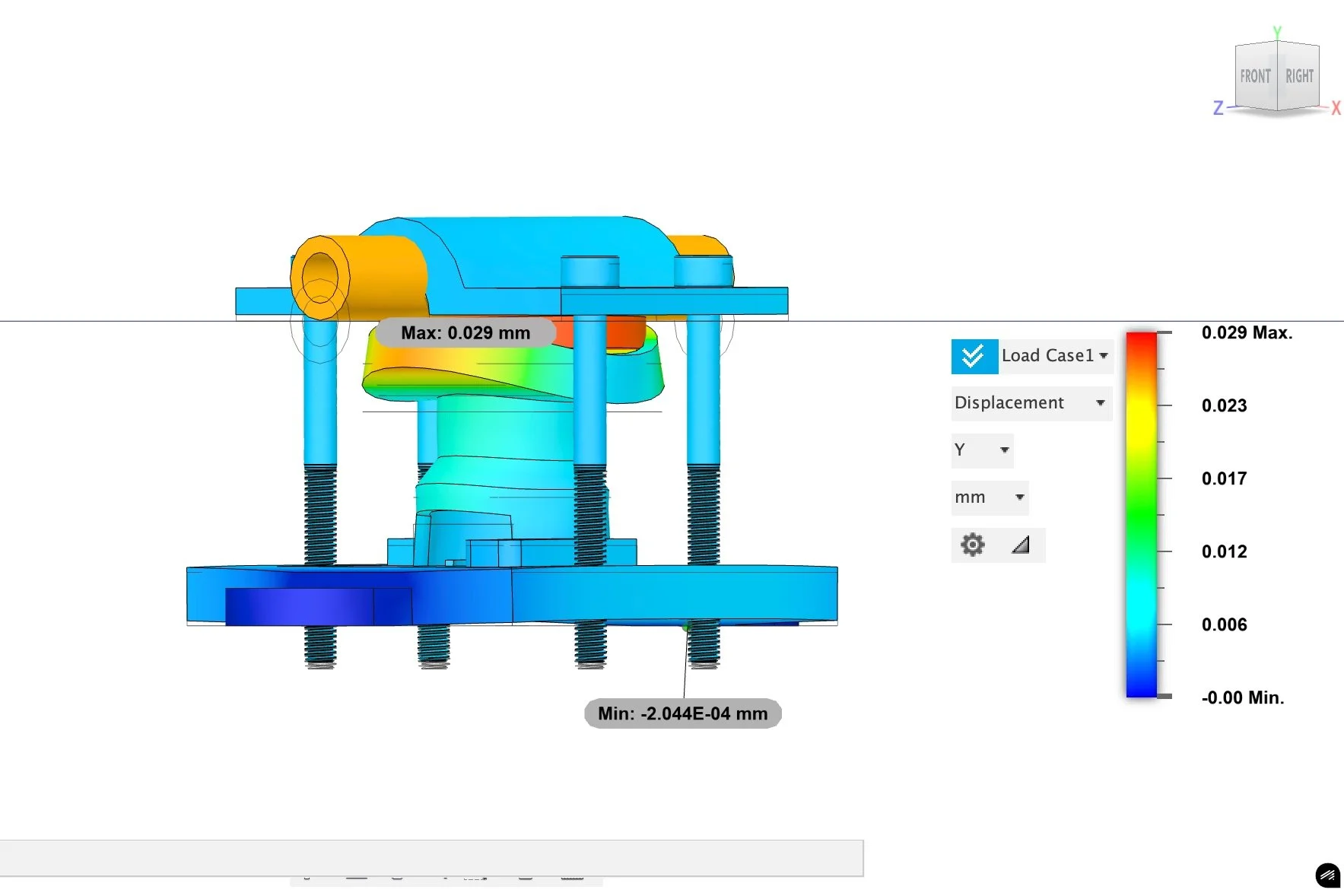

Sensor #1: Applanation Tonometry

Arterial Applanation is another recent development in monitoring cardiac output, specifically targeting stiffness and blood pressure. A semi-occlusion method of blood pressure estimation is preferable in the given circumstance considering the continuous application of the device and location of the sensor, and as such arterial applanation is the preferable method.

All components were designed in Fusion360, where ANSYS Static Studies were computed in order to estimate the applanation area with the spring deformation and elastic properties of the vinyl pipe. Additional tests were conducted with a rotary pump and flow rate sensors as verification.

ANSYS Simulation

Sensor #2: Ultrasonic Sensors

For the ultrasonic patch, the microcontroller controls the signal pulse rate, instantaneous Fast Fourier Transformation (FFT) of the received signal, blood volumetric flow rate calculations, and data storage. A coded sine wave generator on the microcontroller creates a signal with controllable amplitude and frequency that is emitted through the ultrasonic patch. A transmitter and receiver switch switches the patch from transmitter to receiver mode and transmits the received signal to the amplifiers and filters. Finally, a PWM analog pin on the microcontroller receives the signal and executes a program from the “Arduino FFT” library, computing an FFT with the received signal and calculating the instantaneous blood velocity.

All components were designed in Fusion360, and verification was conducted through both a Python Fourier transformation and a hand calculation to confirm estimation of transmitted wave.

Mechanical Iterations

Prototype Alpha V1.0

Initial form factors were modeled, indicating the location of the components and the sensors. Based off of a basic neck massager, the design includes suggested materials such as silicones and injection molded ABS plastic, and potential methods for articulating the components.

Prototype Alpha V2.0

Initial prototypes were developed in order to gauge initial concerns with the physical components of the device. The design is the simplest form and includes a living hinge at the center of the back support to provide the means to clamp the device onto the neck. With some cases testing, some notable issues included modularity in the device’s for neck sizes, proper positioning of the sensors relative to the carotid artery, and rigidity.

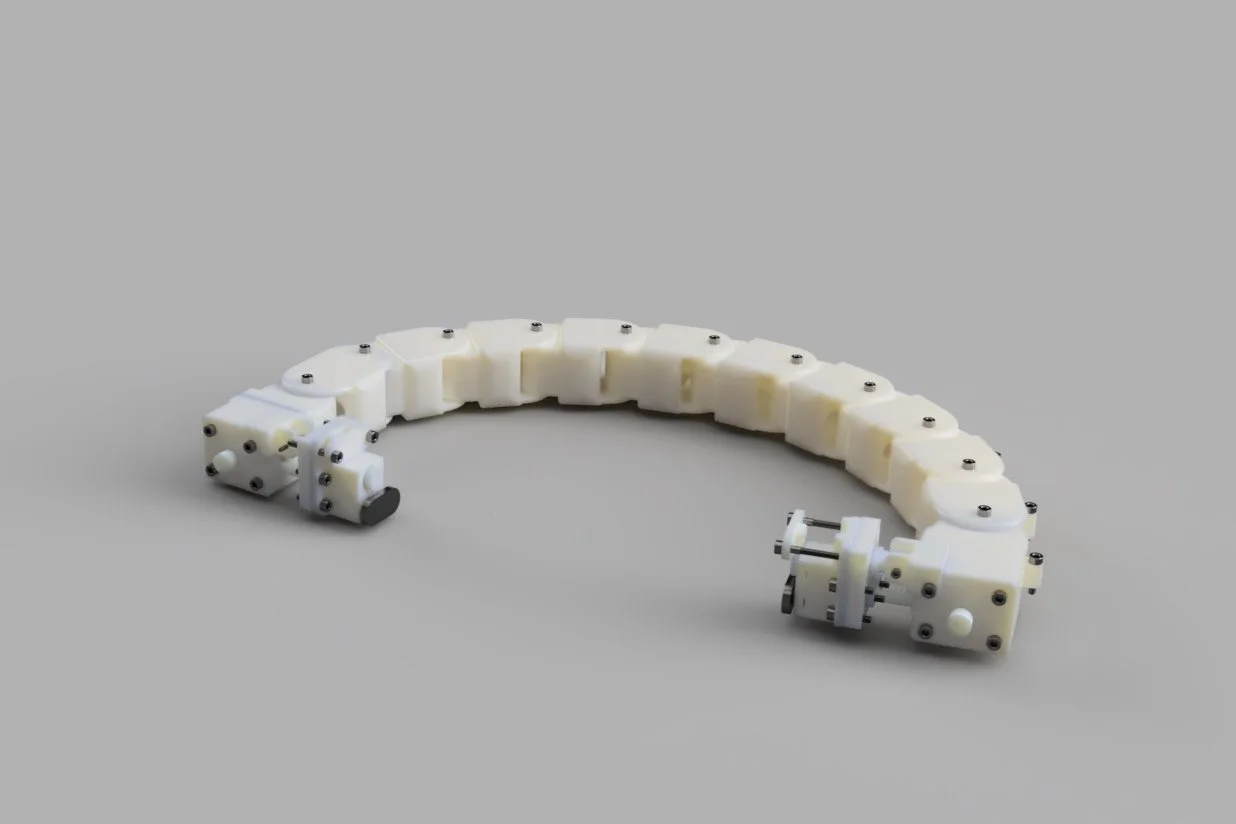

Prototype Alpha V3.0

For the final design, this prototype was a tremendous overhaul of the previous two design and incorporates both concerns from the second design stage and greater improvements for manufacturing. Detailed neck links for modular neck adjustment, gear systems for a rack and pinion to engage the sensors, and multiple articulating parks for future adjustments in the design.