Blade Airfoil Optimization with ANSYS

MAE 4700: Finite-Element Analysis Approaches

Situation

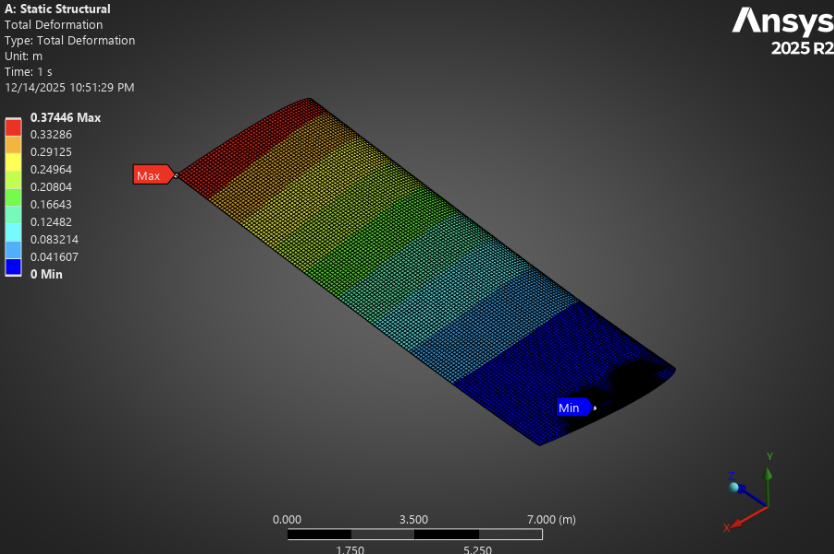

As a practice of this design process, optimize a given blade’s weight for specific Von Misses stresses and tip deflection by leveraging finite-element analysis methods in ANSYS Static Structural

Focus on parameters such as number of spars and ribs in the wing, thinning the skin, and altering the placement of the various components in the design.

Outcomes/ Constributions

Leveraged design parameter optimization in ANSYS Static Structural compute structural performance of 4 different wing blade geometries

Computed the model with 3 different numerical solution methodologies, specifically with different mesh refinement such as automated element optimization

Converged on a specific wing geometry, including ideal rib-spar thickness and placement, to reduce the blade’s weight by ~41.80% and operate within ideal conditions

Relevant Skills

ANSYS Structural, Design Optimization and Iterative Design, Defining Mathematical Models and Numerical Solutions, Report Writing