Anti-Kink Coils for Synthetic Vascular Grafts

Cornell University Biofoundry Lab and Anova Biomedical Inc.

Situation

Develop manufacturing technology and preliminary models for a novel anti-kink coil designed to increase patency of synthetic vascular grafts produced by Anova Biomedical Inc. and Dr. Yadong Wang

Optimize pre-soruced equipment such as plastic extruders to create an automated, well-regulated method for producing multiple coils

Outcomes/ Constributions

Design and standardized a PET anti-kink coil system for synthetic vascular grafts, leveraging FEA-guided design optimization to meet ANSI 7198-2001 requirements

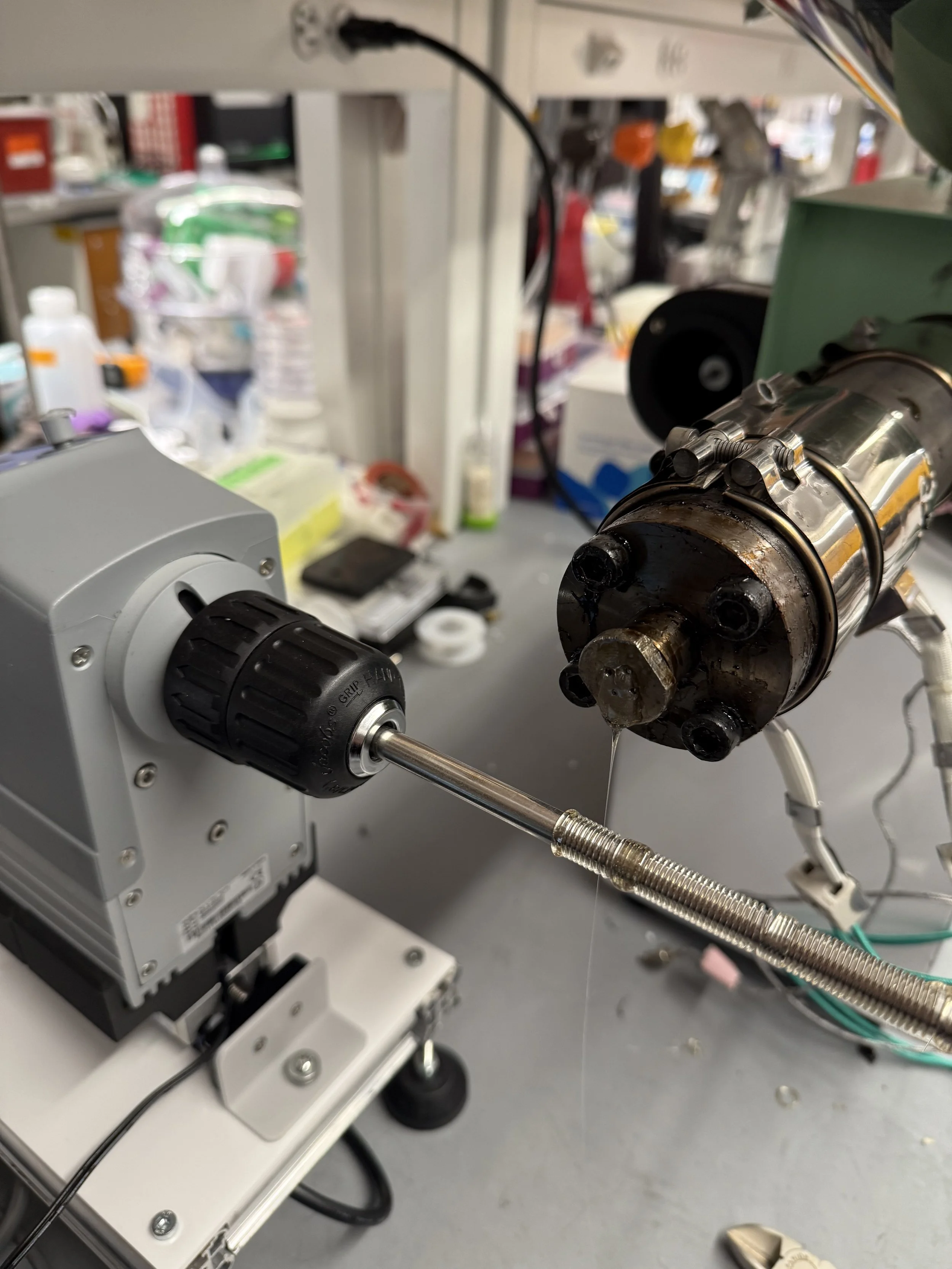

Developed an automated, custom manufacturing workflow by integrating a motorized linear stage, mandrel spinner, and extruder to create a repeatable, software-controlled process

Successfully fabricated and validated 12 anti-kink coils across multiple design variants, successfully characterizing kink resistance and mechanical strength

Provided +20 pages of extensive documentation in a design report outlining performance metrics, usability performance in accordance with ANSI 7198-2001, and ANSYS Fluent reports on extruder head flow

Relevant Skills

3D Modeling and Rendering, Root Cause Analysis, ANSYS Fluent, ISO Standards and Documentation, manufacturing methodologies, materials, Report Writing, Engineering Presentation/ Communication

Documentation limited due to confidentiality and proprietary information included