AeroDry: The Closet Clothes-Dryer

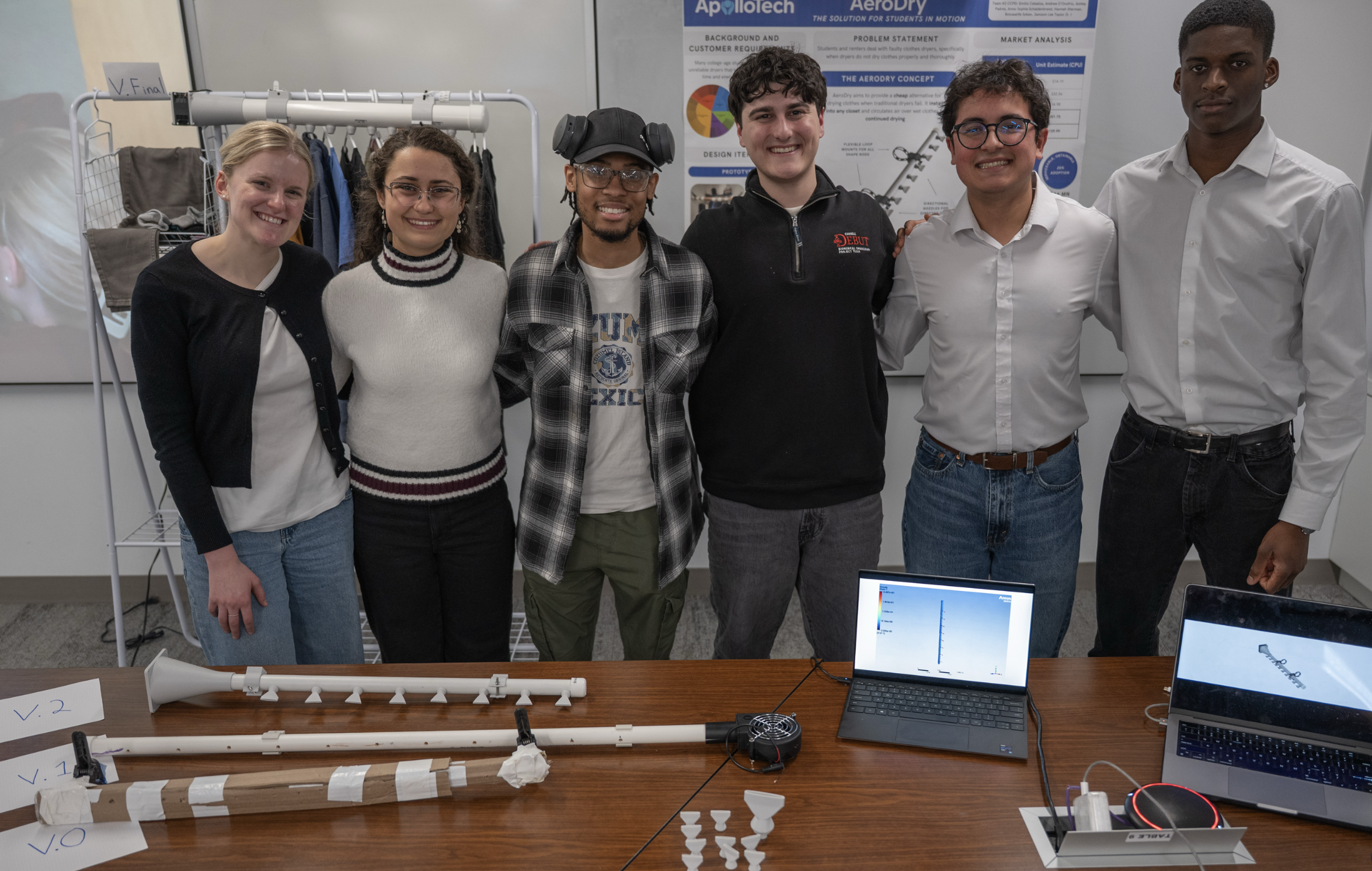

MAE 4341: Innovative Product Design via Digital Manufacturing (ApolloTech Team)

Situation

Identify and contextualize a core need in the Cornell college-student experience (as required by the MAE 4341 course staff)

Propose an electromechanical solution that is realistic for a typical student to purchase and use on a typical day-to-day, including basic verification/validation testing, functional prototypes, and in-depth market analysis

Present to a panel of industry specialists for feedback on start-up potential

Outcomes/ Constributions

Conducted +10 customer discovery interviews with Cornell students to survey and evaluate needs within the community

Lead Triz Analysis for translating 8 major product requirements and 10 engineering constraints into ideal electromechanical prototype designs for 3 prototype iterations

Rapid-prototyped 5 different iterations of final prototype (V3.0) for experimentally testing outlet airflow efficiency and drying time

Conducted ANSYS Fluent for final prototype iteration to affirm hand-calculations of outlet velocity efficiency with >90% accuracy

Assembled research poster and high-quality renderings presented to potential investors

Relevant Skills

3D Modeling and Rendering, ANSYS Fluent, Customer Discovery/ Needs Identification, Report Writing, Engineering Presentation/ Communication

Background

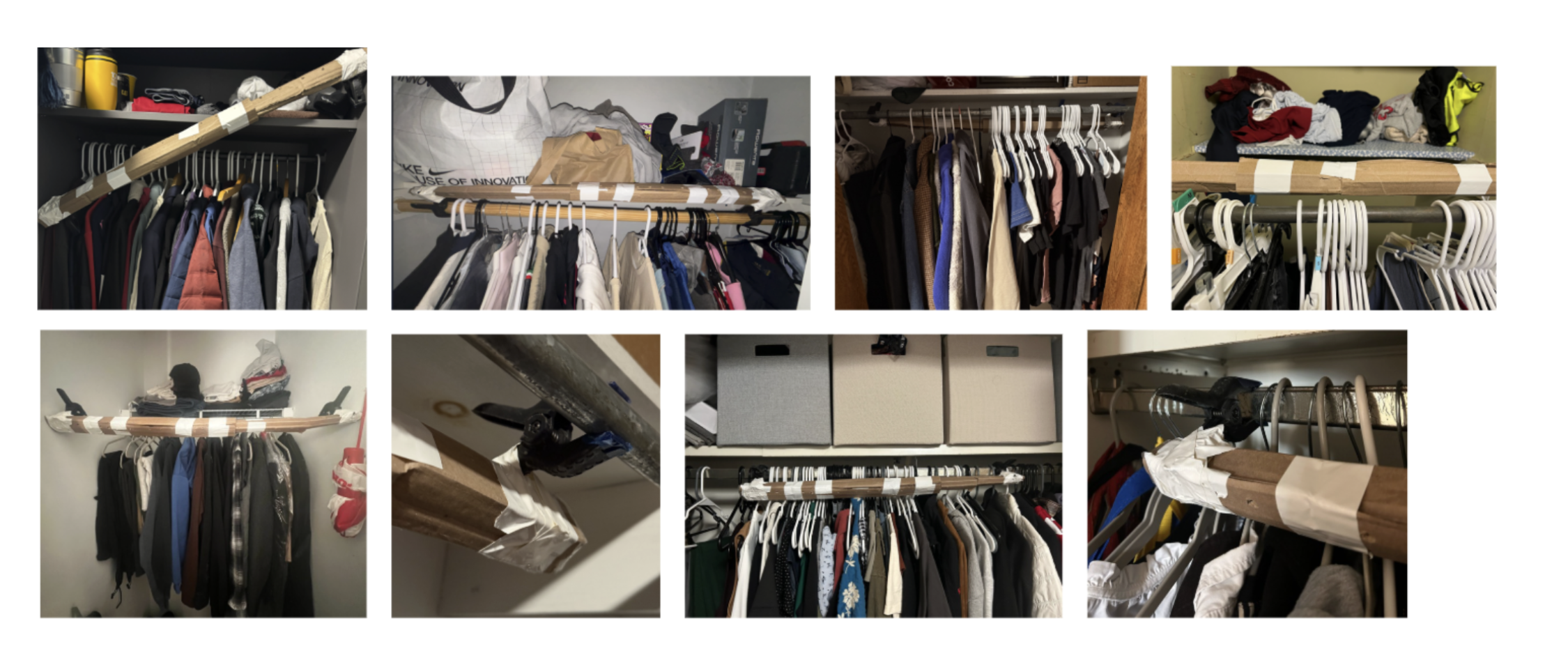

For MAE 4341: Innovative Product Design via Digital Manufacturing, our team was tasked with innovating a new physical product for college-students at Cornell to improve the day-to-day experience. With this, we ended up collecting +150 empathy fieldwork data points through customer interviews and immersion programs to learn about their daily routines. We identified issues with laundry drying being a troublesome issue in most students lives, and as such we aimed to create a device that would improve the clothes-drying experience independent from college/apartment drying equipment.

TRIZ Product Design Analysis

On the team, I focused on design and manufacturing of the components for the all of the iterations of the AerDry prototype, in addition to simulations and testing. Beyond rudimentary building, I integrated TRIZ problem-solving in order to identify key deliverables for improvement between design stages and meet customer requirements established from the initial discovery phase. For context, TRIZ (Theory of Inventive Problem Solving) method is a problem-solving methodology used in product design that provides a systematic and creative approach to innovation by identifying and resolving contradictions. The following is the integration I lead of TRIZ solution for each product stages:

Prototype V0 (Form Factor)

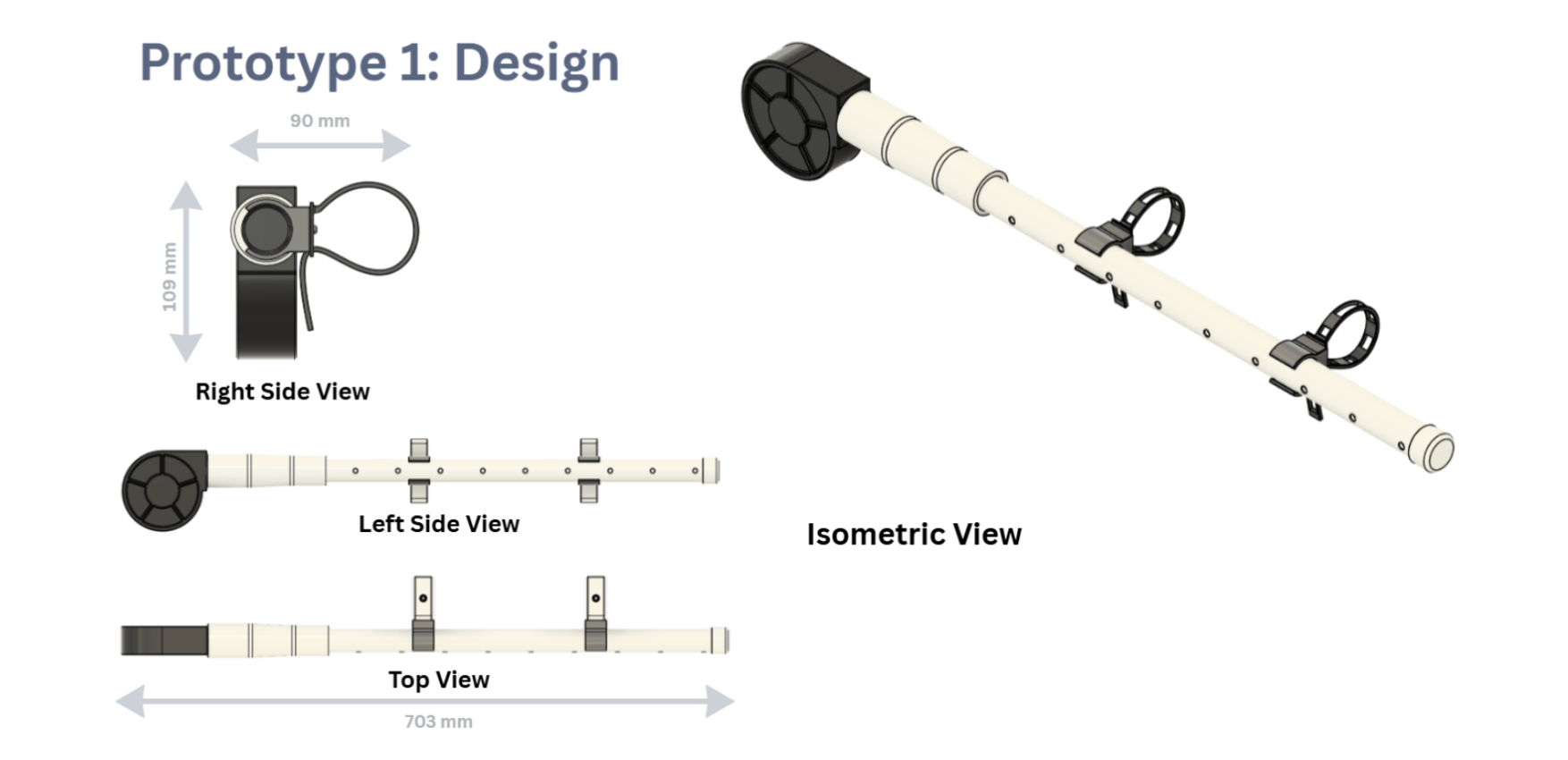

Product 0 (Form Factor): This prototype was made to primarily test the fitting and aesthetic aspect of the product, constituting TRIZ engineering parameters associated with form. This specifically includes the weight of the stationary object, the length of the stationary object, and the volume of the stationary object. As such, our design initially included a telescoping component and was minimally sized. Our initial material, more specifically cardboard, was a good material to use because it was lightweight, but our team anticipated that this material would directly contradict later engineering parameters, such as ease of manufacturing, strength, and durability of stationary objects.

Relevant TRIZ Engineering Parameters

Segmentation (TRIZ, 1) - Modular assembly and disassembly played a crucial role in segmenting the body of the air chamber from the air-producing component and from the fixturing clamps

Preliminary Action (TRIZ, 10) - All components are preinstalled/ preassembled, with the only control options being clamping the device into the closet and powering the fan by plugging into the wall

Periodic Action (TRIZ, 19) - The fan will ideally be operated only during, dynamic components have been discussed, but would overly complicate the simplicity of the design for the device

Mechanic Substitution (TRIZ, 28) - Replace the complex mechanisms of the fan with a simplified DC fan

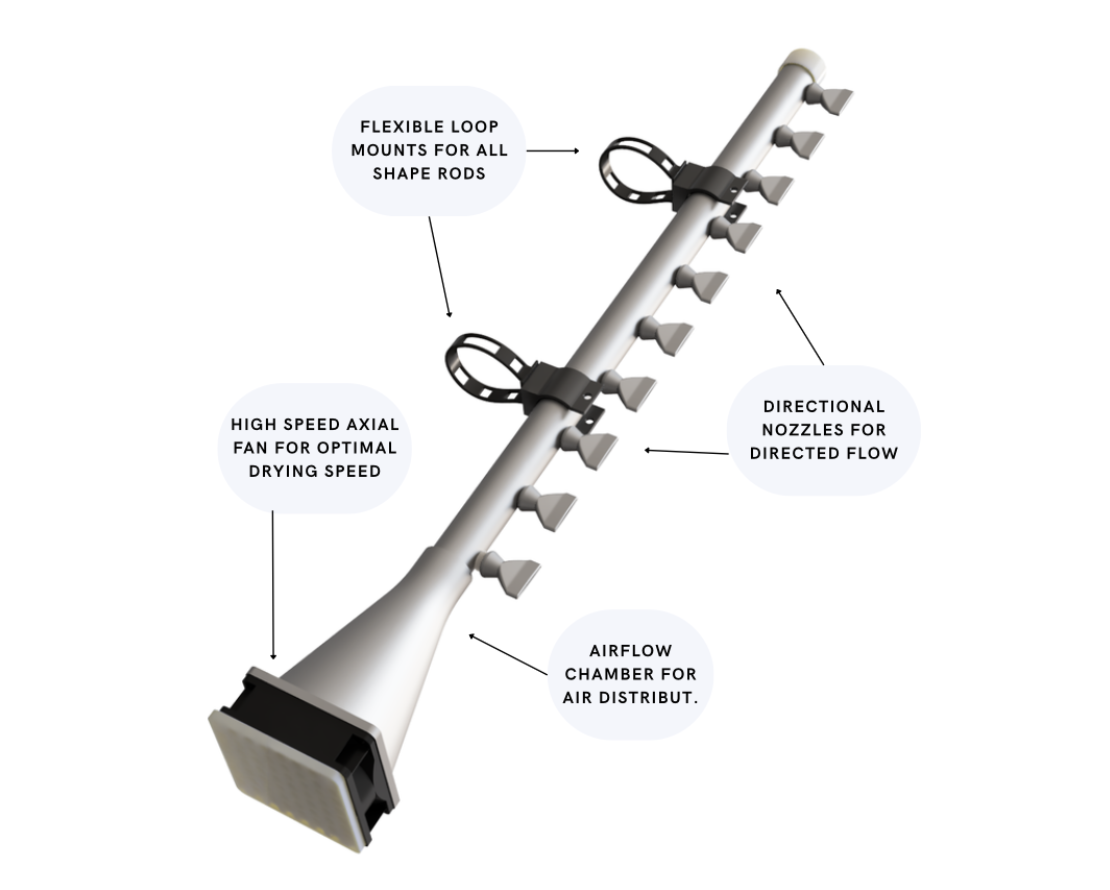

Parameter Changes (TRIZ, 35) - The major parameters involve a change in pressure, as the pressure generated from the fan into the air-tight chamber should be much higher to create high-velocity nozzle streams

Prototype V1

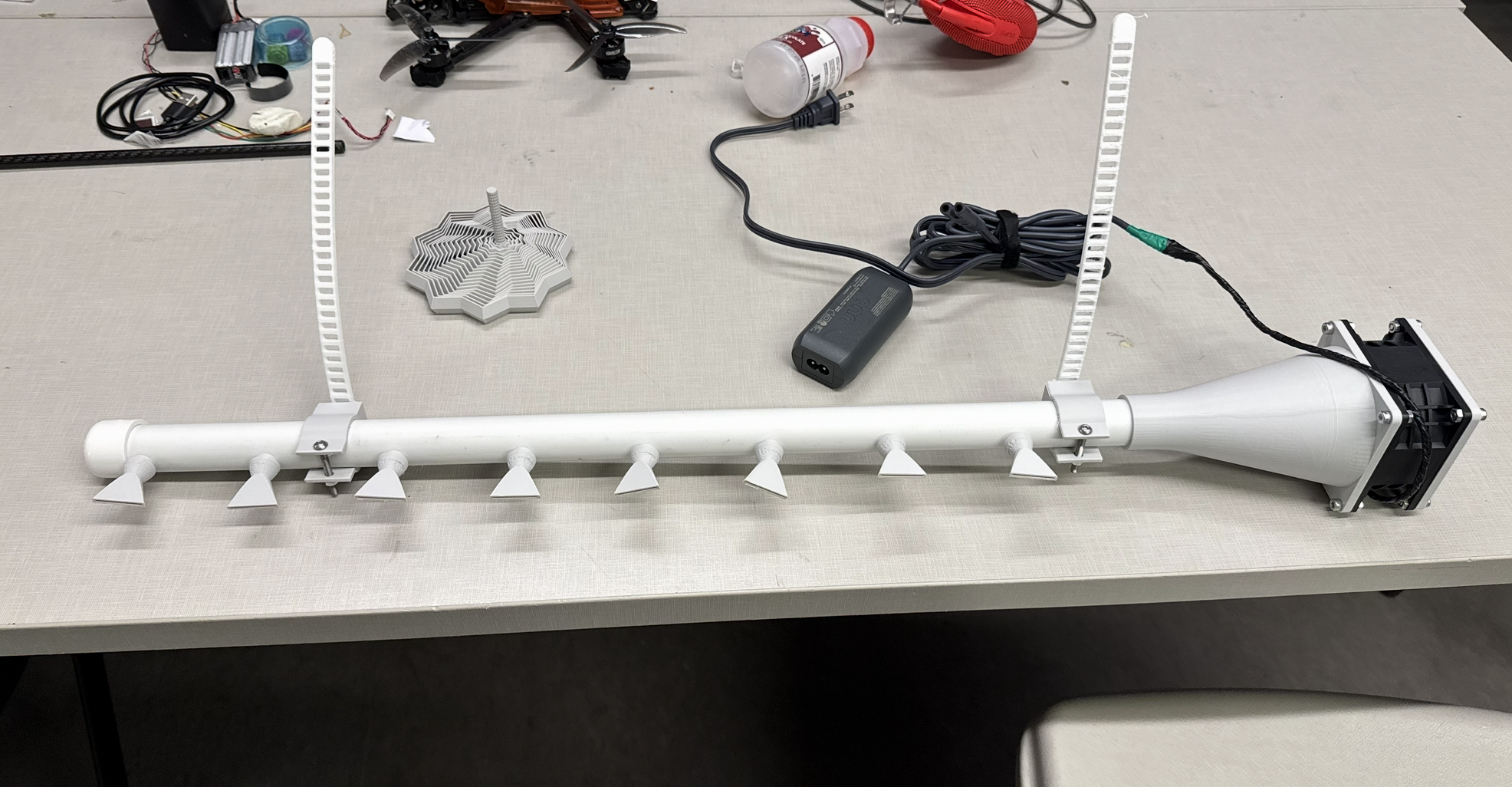

Product 1: This prototype was made for functional and drying efficiency analysis, including all new fans, tubing equipment, and fixturing mechanisms. First, we bought a low-speed centrifugal fan from Amazon with a circular profile compatible with a ¾ inch diameter, and scheduled 40 PVC pipe. With this, we created a long tube body with 8 ¼ inch holes, and connected one end to the fan and capped the other end. One of the main contradictions to arise with this additional step in prototyping was the balance of length and volume of stationary objects with power and durability. These primary engineering parameters proved difficult to balance, and although the TRIZ solutions recommended changing parameters of the device's structure, our team was unable to determine an effective method for implementing these suggestions and opted to lower the importance of the length parameter.

Relevant TRIZ Engineering Parameters

Local Quality (TRIZ, 3) - The open-hole method for the following prototype was inefficient for directing airflow, and as such, nozzles are needed to more specifically direct the output from the fan

Universality (TRIZ, 6) - Improve the utility of the clamps to be more accessible for different size/ shaped clothing rods

Spheroidicity (TRIZ, 14) - The design of the device needs to optimize smoothness to maintain better velocity profiles for air throughout the air, especially near the fan-pipe interface

Partial/ Excessive Action (TRIZ, 16) - Fan performance is far too low, and as such, excessive fan usage may be required to improve performance

Prototype V2 (Final Prototype)

Product 2: For the final prototype, our team aimed to further optimize the output of our device and validate the efficacy in a general use case. After finalizing the learnings from prototype 1, our team aimed to improve the volumetric flow rate from the fan, the direction of the air, and the durability of the design. Although major components remained similar to the previous design, the fan was boosted to a much higher CPM, and nozzles were added to the holes within the design.

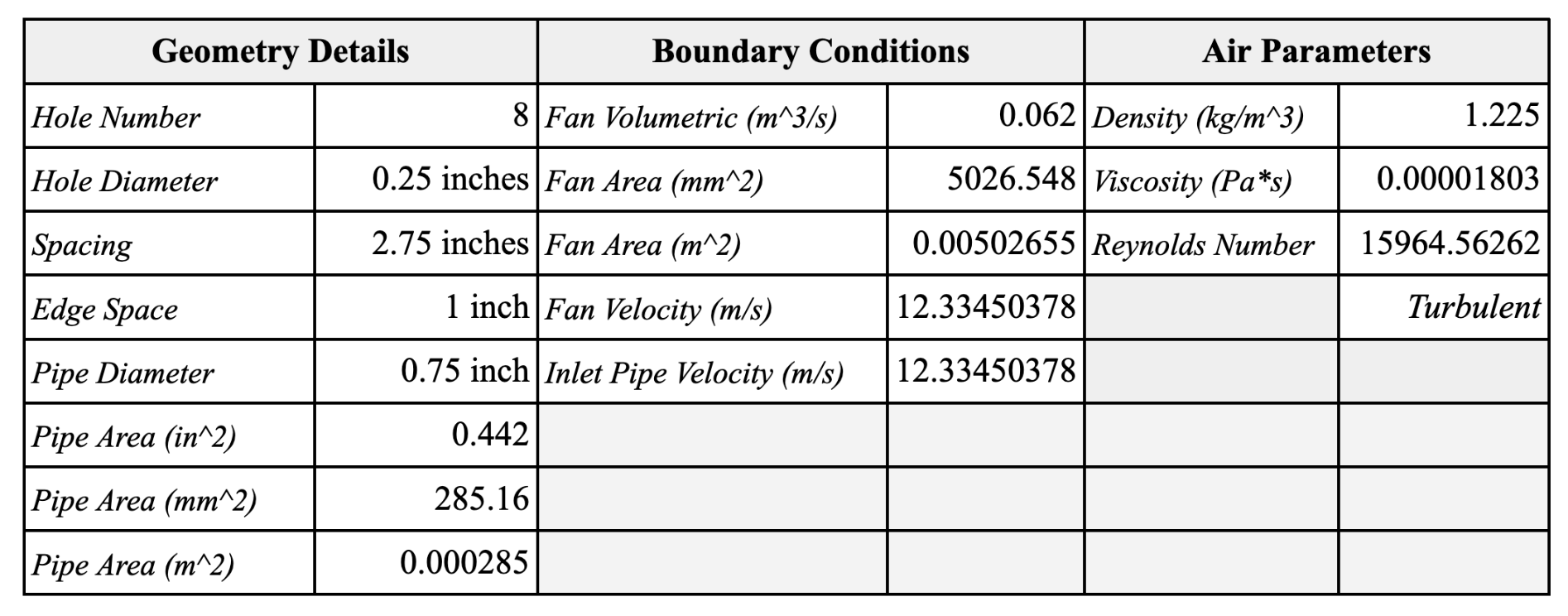

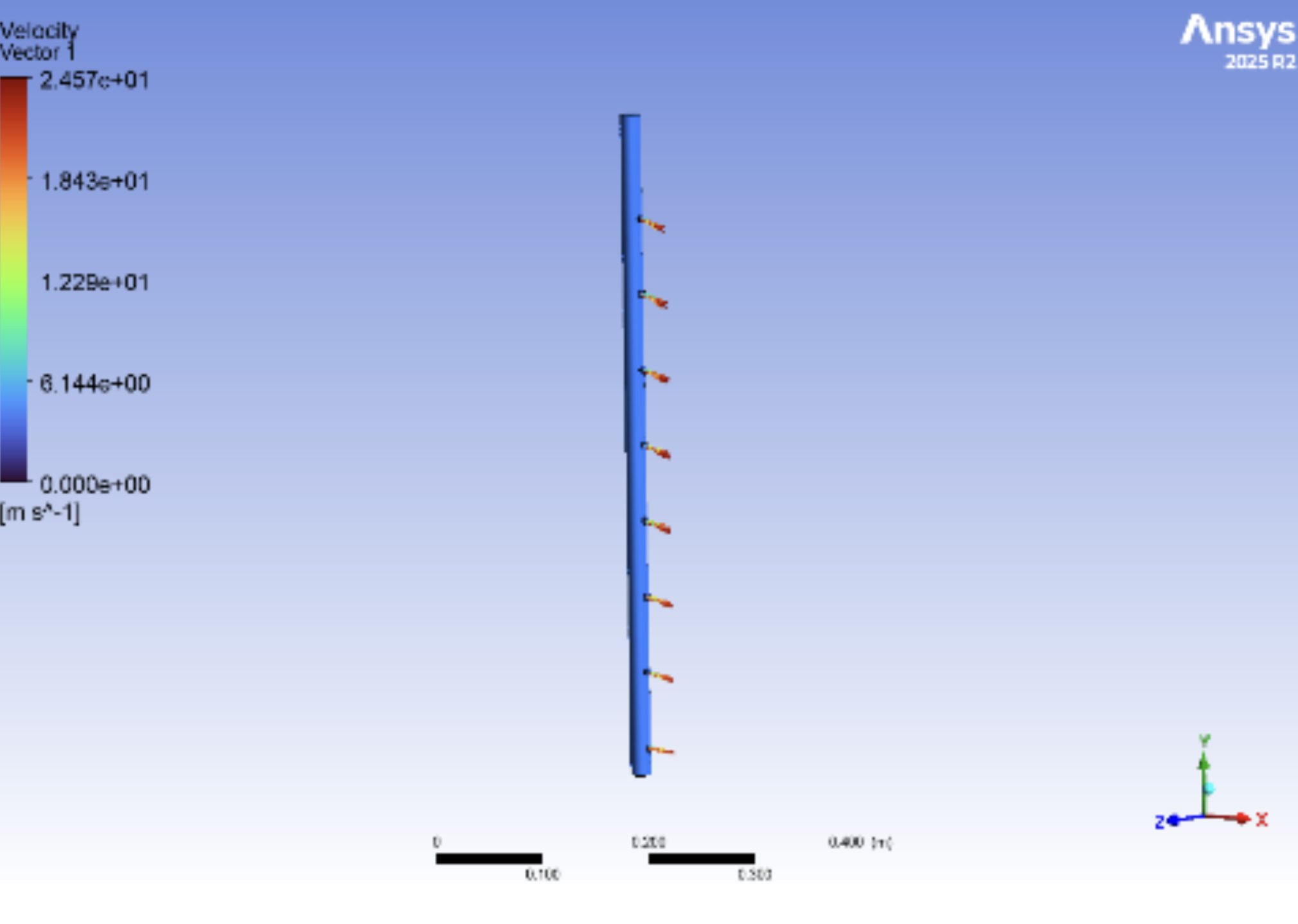

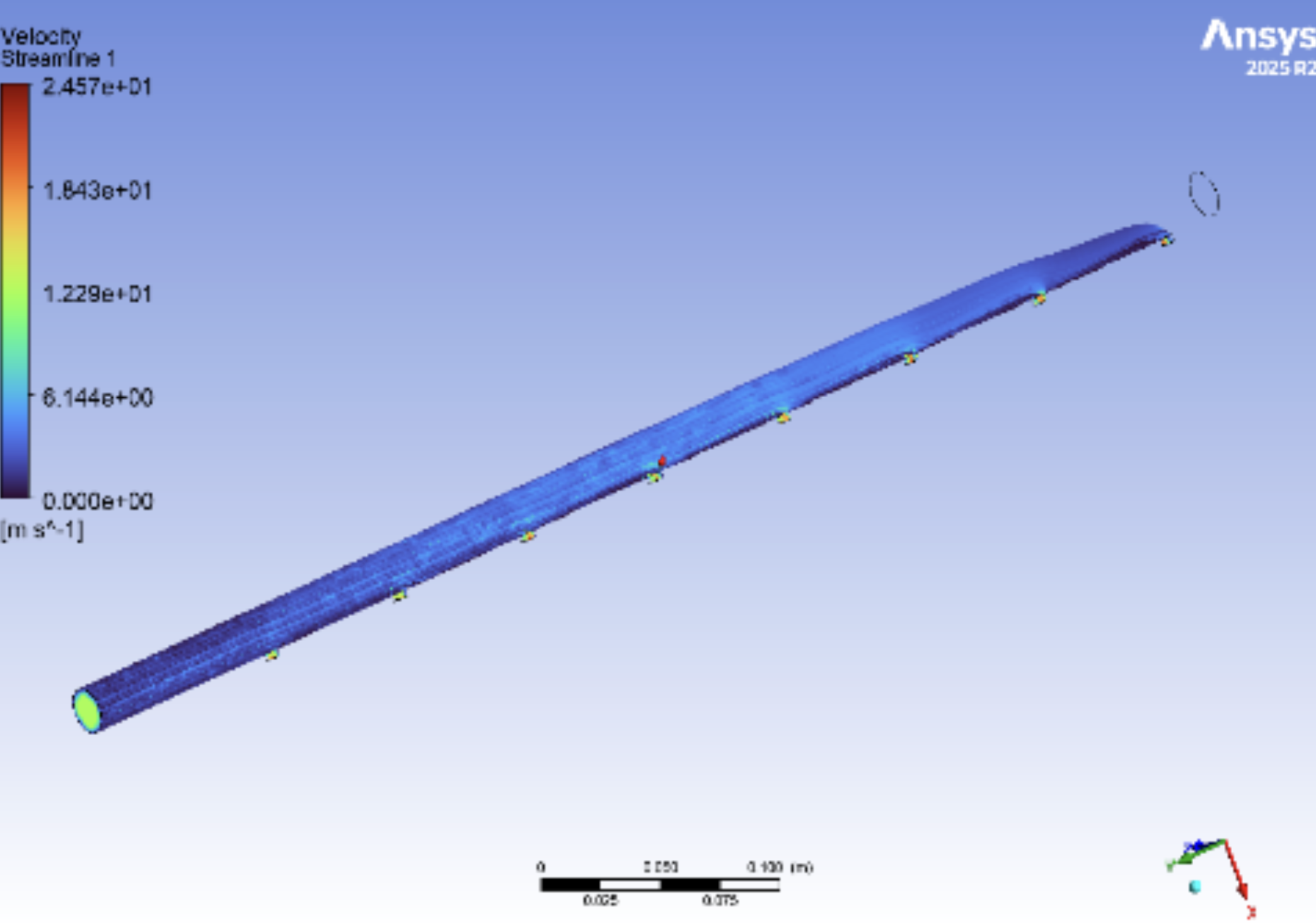

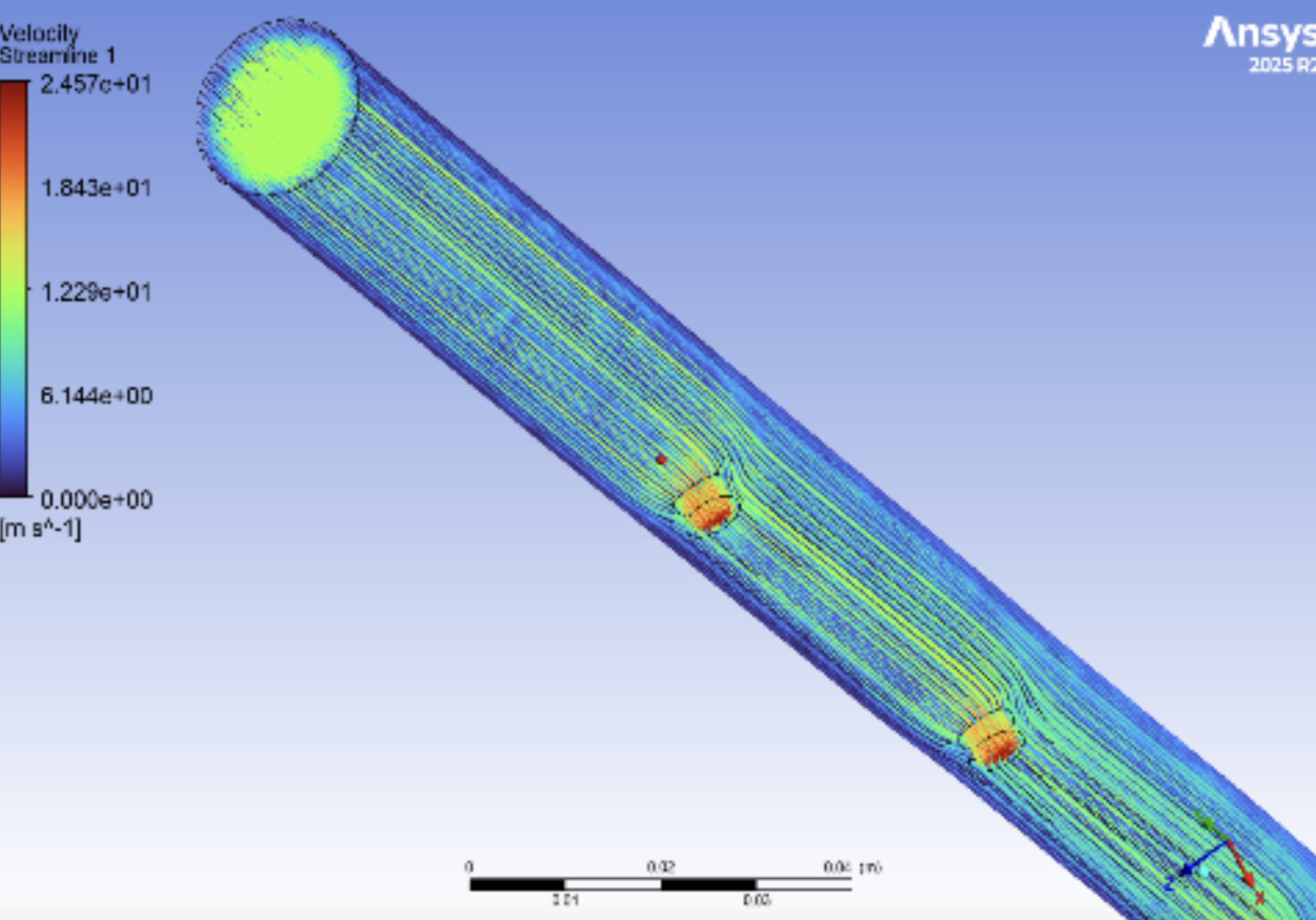

ANSYS Fluent Analysis

A rudimentary FEA fluid model was created to demonstrate the profiles of air flow throughout the chamber of the device. With this, outlet velocity and streamlines within the chamber are visualized to determine preliminary efficacy and inform later design issues. Internal fluid geometry was developed in Fusion360 to model the internal area of prototype V2. Additionally, boundary conditions were experimentally determined from the fan prototype V2 datasheet provided through DigiKey, and ANSYS Fluent computed the individual elements of the model. The following are the preset conditions for the model and the results of the ANSYS Fluent computation:

Exit Velocities across Outlets

Full Velocity Streamlines (~100)

Inlet Velocity Streamlines (~100)